Plastic houses

The Wasteland of L’Escalette – Goudes, Marseille 13000

JULY / OCTOBER 2017

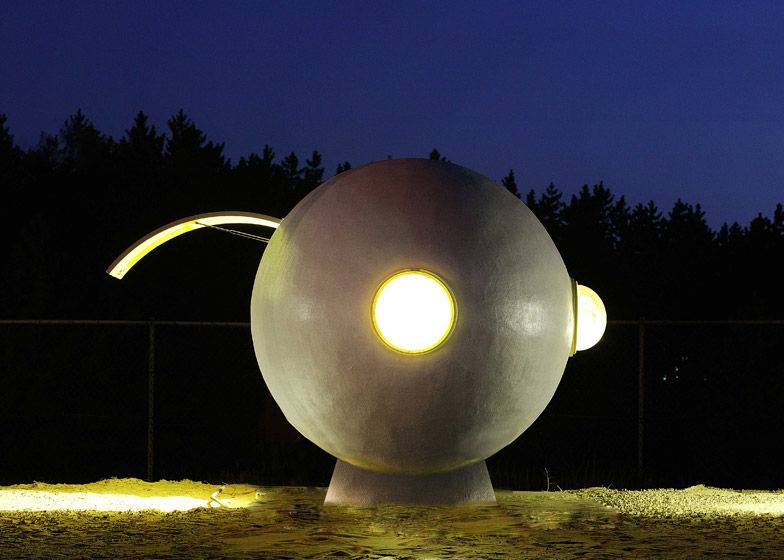

At the Light Sculpture and Architecture Park

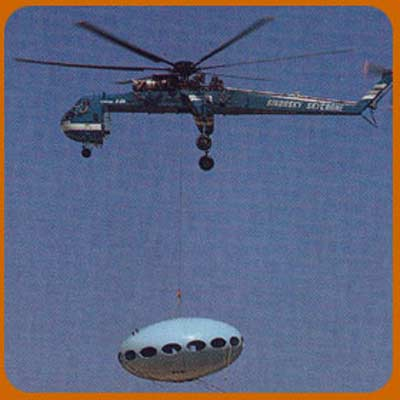

(1933-2013) Is a prefabricated home designed by the Finnish Matti Suuronen

One hundred copies of this house were built between the late 1960 and the early 1970. Their distinctive shape in the style of flying saucers and their entry into airline airlock make these very popular among collectors constructions. Futuro consisted of polyester plastic and fiberglass, measures about 3 meters high 8 m in diameter.

(ME) VIRGINIA MANEVAL

The Futuro House de l’Architecte Matti Suuronen

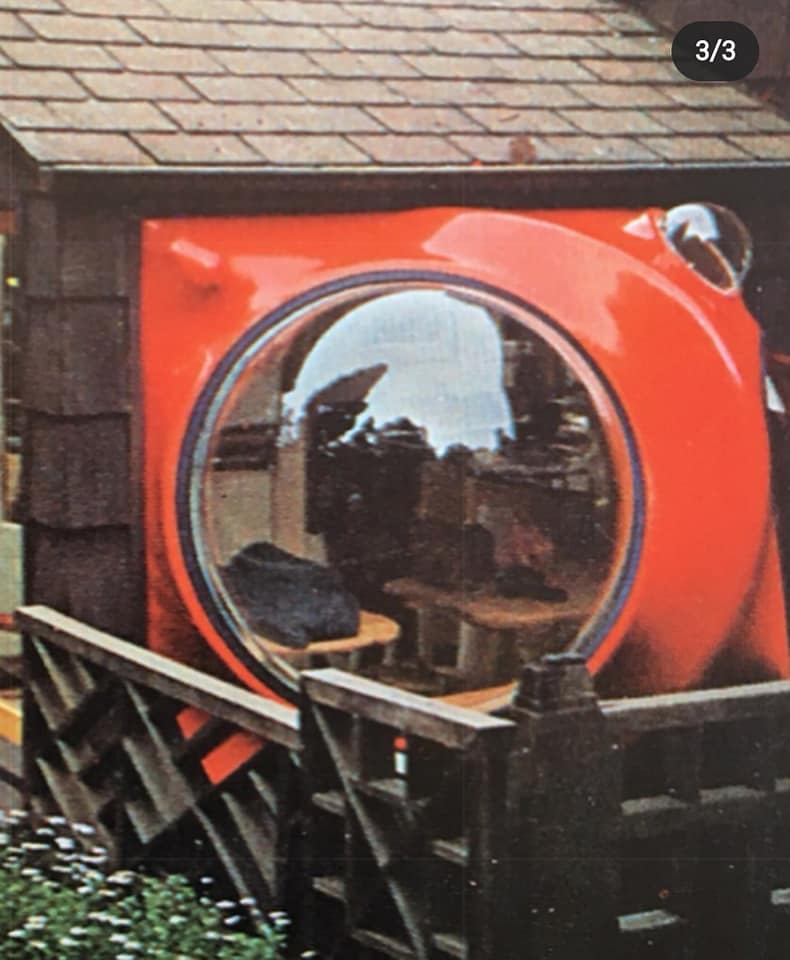

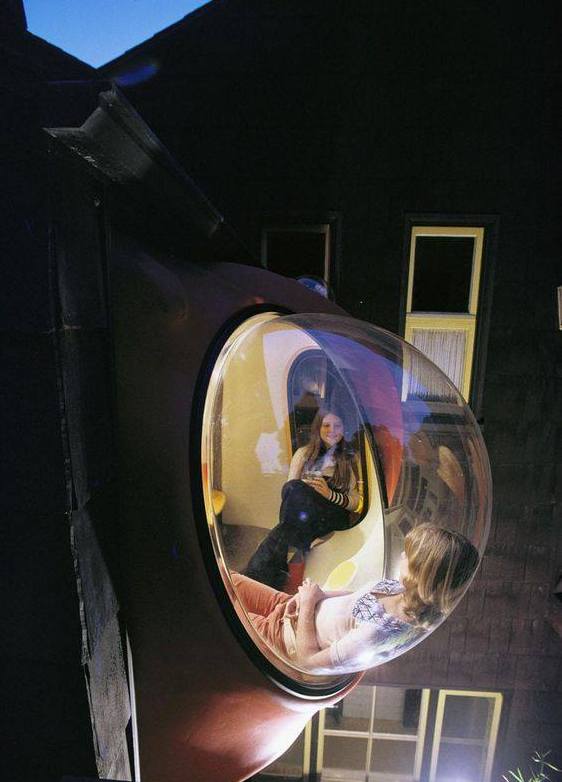

Ant Farm – Micro House

Ant Farm, Poole House Remodel – San Francisco. California, 1974.

Ant Farm Micro House US” Poole House Remodel ” San Francisco. 1974. The red fiberglass structure.. A bubble for everyone. Located in San Francisco, in California, the addition of the Pool House a space created for children designed by the collective of Design Ant Farm in the early years 1970.

Cuisine, ant farm dining room : published in Domus 545 / Avril 1975.

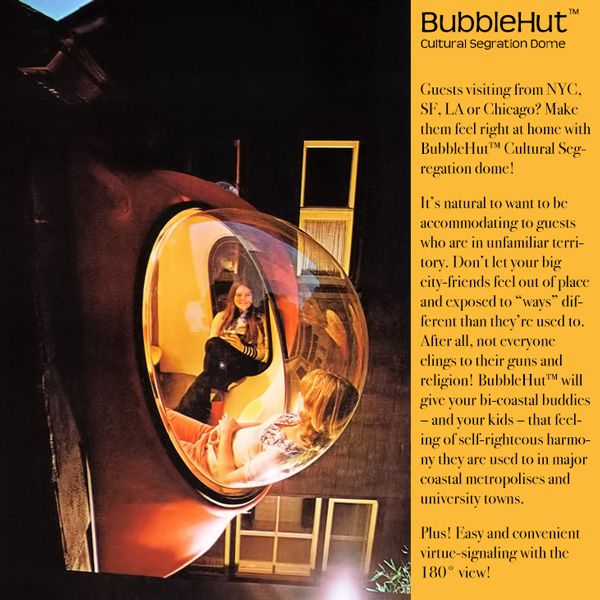

BUBBLEHUT

A fiberglass structure, applied to an existing wooden house, is painted with the & rsquo; outside red and yellow in & rsquo; interior.

ELLE Women's Magazine (1973) ” Plastic houses ” (below)

Text and photos: AA Architecture of Today – 1972

The sandwich elements are manufactured by various processes :

1. cover layers doubling a prefabricated core (for example sheet metal).

2. top layers are pressed directly on a prefabricated core

(for example polyester reinforced with glass fibers) and bonded during curing thereof.

3. Prefabricated layers are directly attached to the core by applying foam

(for example with rigid polyurethane foam).

4. Core and layers produced in a process (structural foam).

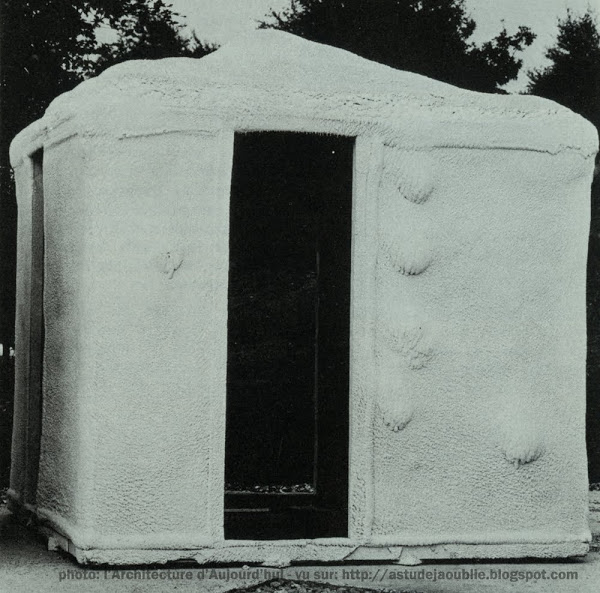

3 H Design – plastic foam habitat – IKA '71 tree house, Minimalhaus – Plastic Foam Habitats Design: 3 H Design: P. Hübner, J. Beieler, P. Breitenbücher et R. Schneider (Stuttgart) Creation: 1971.

The plastic foam is a lightweight material with a cellular structure. The gas filled cells make it light and clean with perfect insulation. Today, almost all plastics are transformed into foam, which means, by the addition of suitable agents, they swell and, according to the methods and materials, become soft elastic, rigid foams, closed or open cell. The hard plastic foams based on polystyrene, PVC, phenol resin, polyurethane and polyester may be used as core material in sandwich constructions and freestanding. The use of plastic rigid foams opens new perspectives since these materials are manufactured not only in plants but also directly on construction sites. this allows, for foam spray for example, to transport them in the liquid state.

Biography :

John Benjamin Maneval Architect

1963 Studies – Fabrication: 1968 – 1980

1964-1965 Preparatory Study

1965-1968 Phase study

1965 Creation of technical and financial framework: Bati-Plastic

1966 Pre-market study

1966 Prototype Defense (Paris)

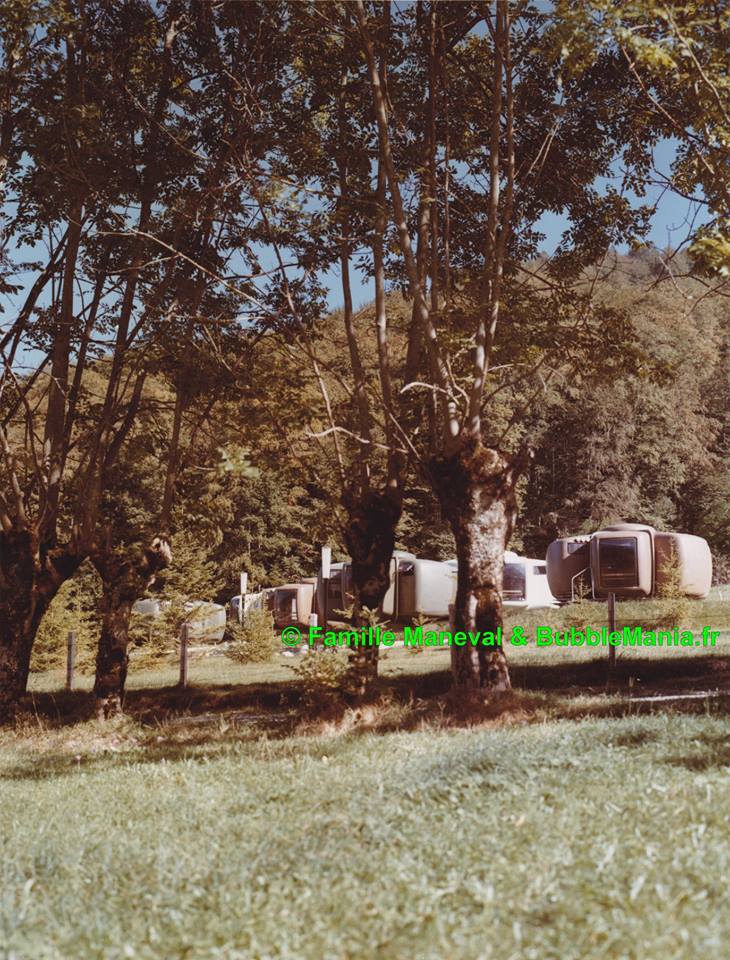

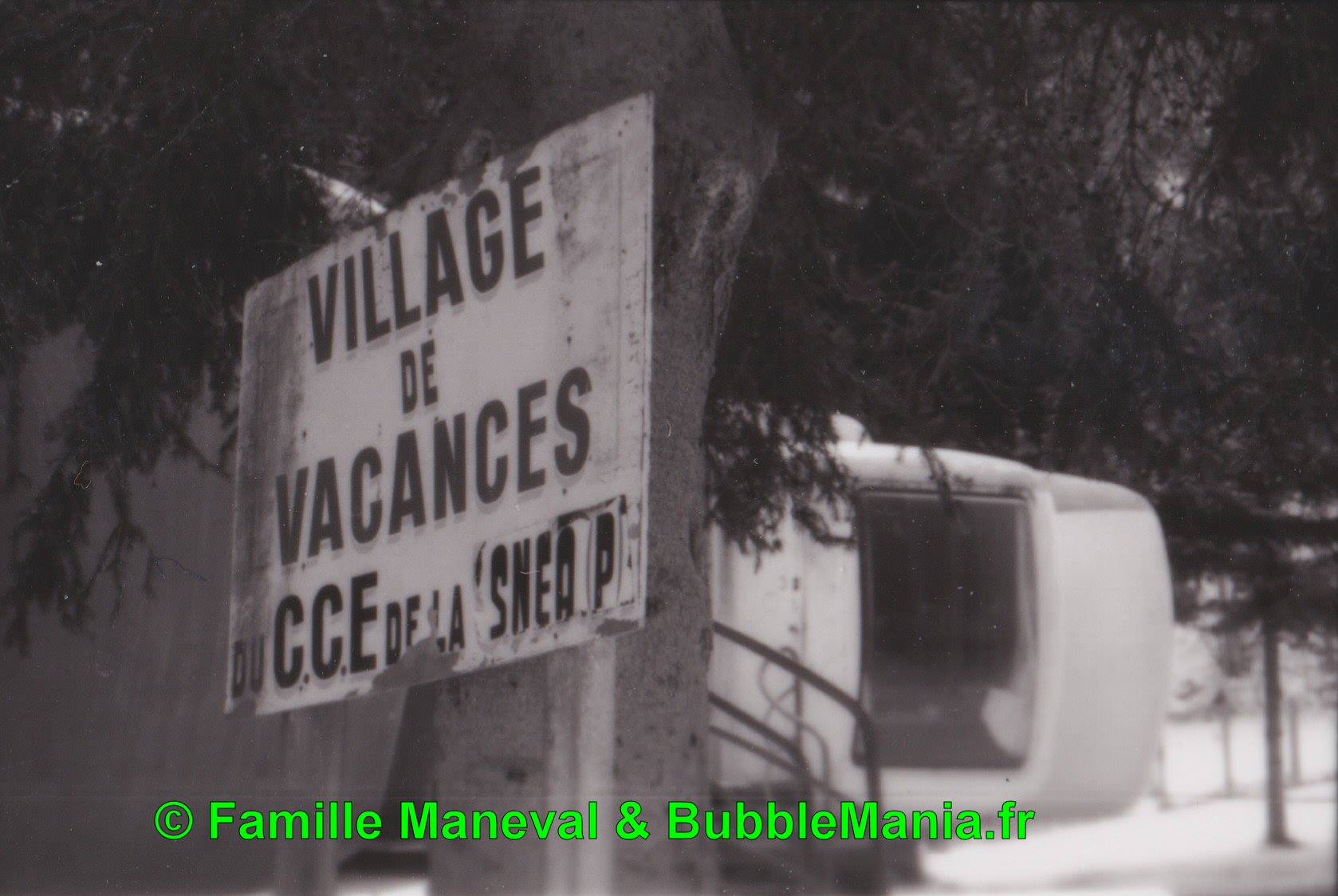

1967 experimental set (Holiday Village Gripp 65710, Hautes-Pyrénées)

1967 Filing a Patent (Know-How)

1968 Sale of patent

1968 operational phase

1969 Placing manufacturing

1968-1969 Establishment of marketing and advertising network

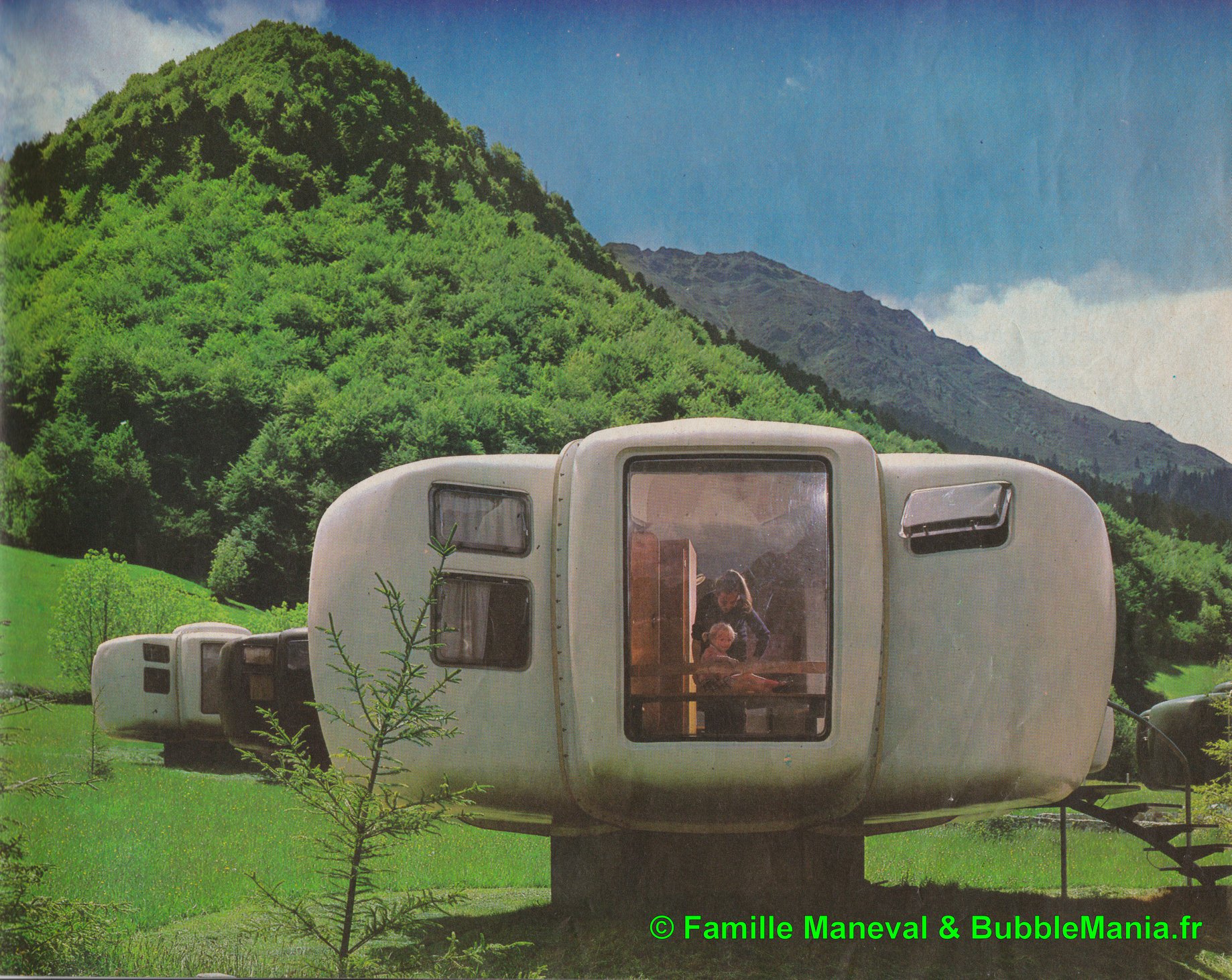

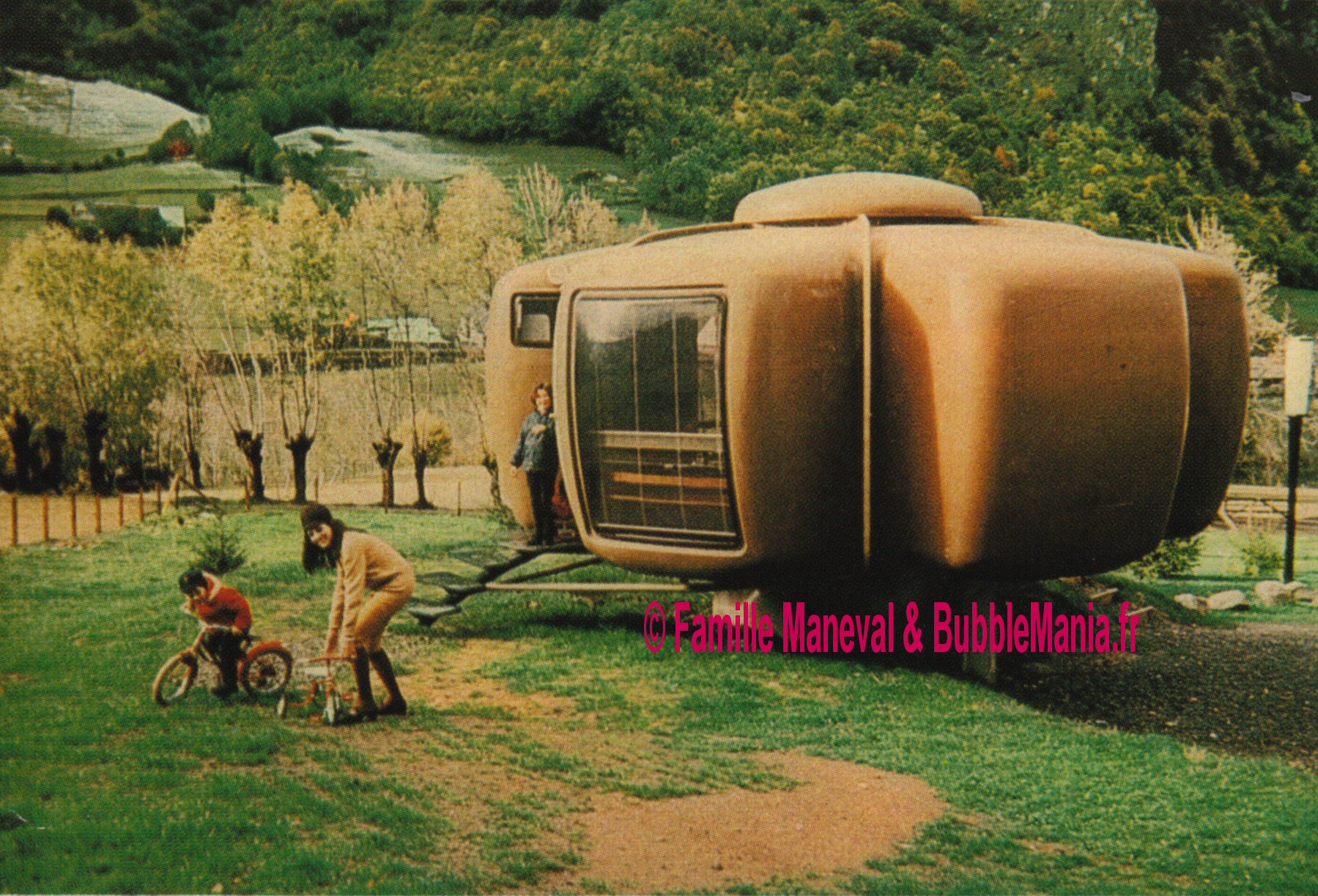

1969-1970 Manufacturing of “Bubble 6 shells”.

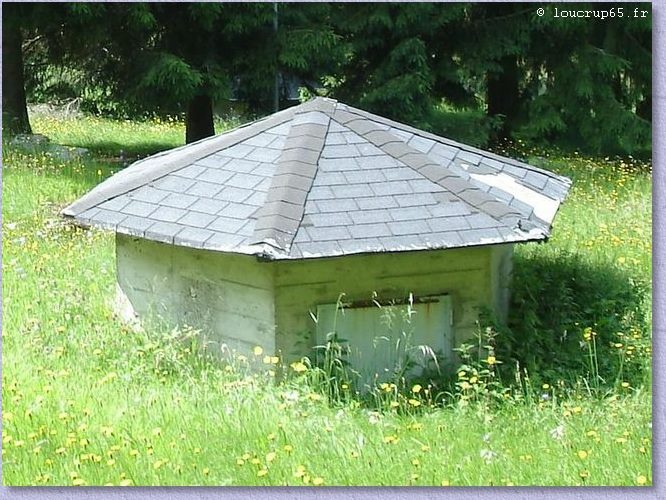

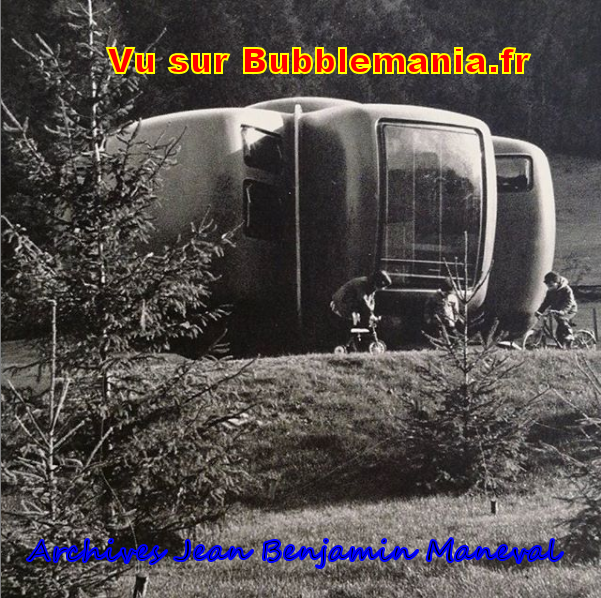

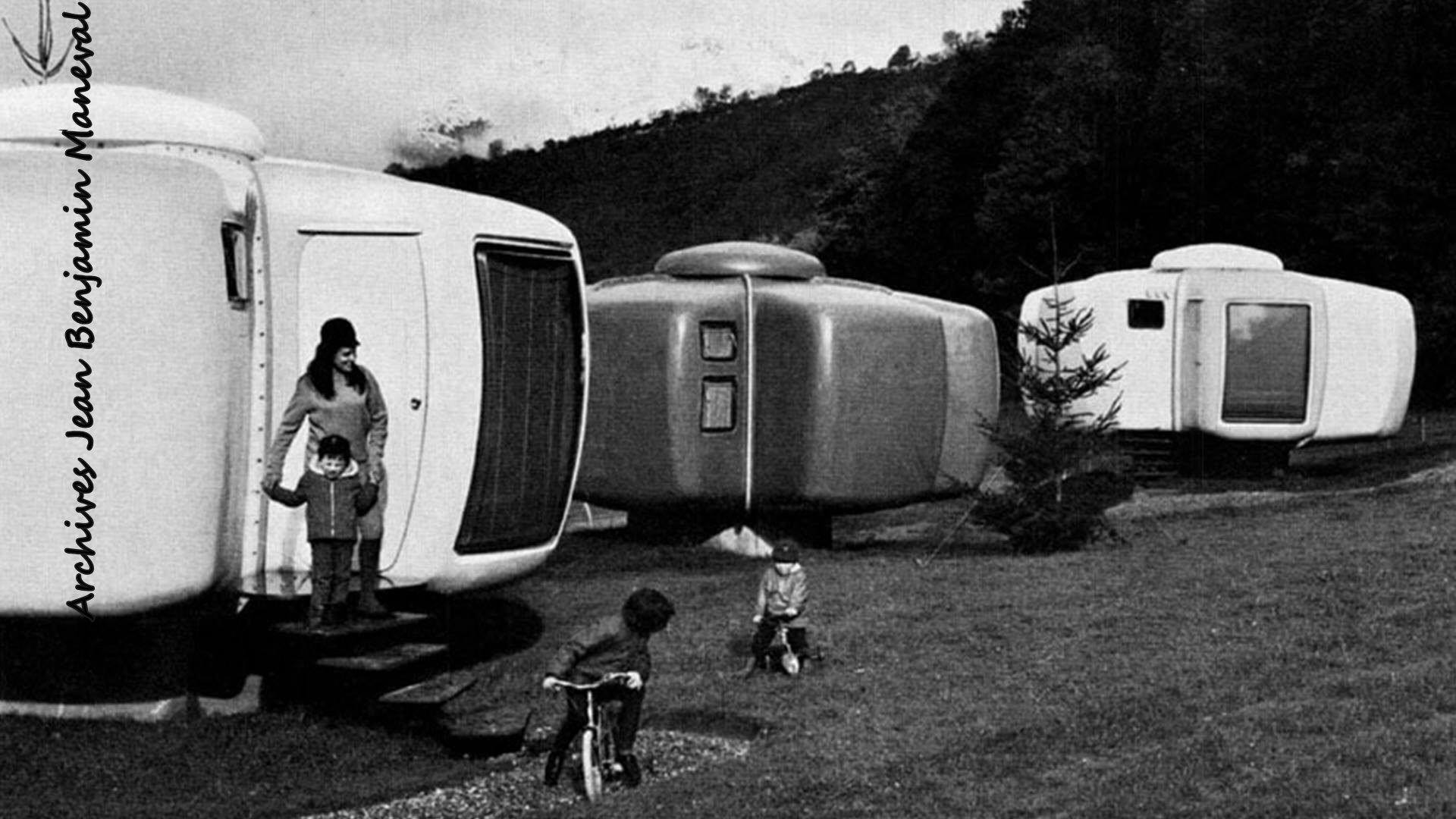

PROTOTYPE of BUBBLE SIX CASES JEAN BENJAMIN MANEVAL

flu, Artigues, Campan 65710 Midi-Pyrenees.

Bubble Color Six Hulls by Gripp (Holiday center)

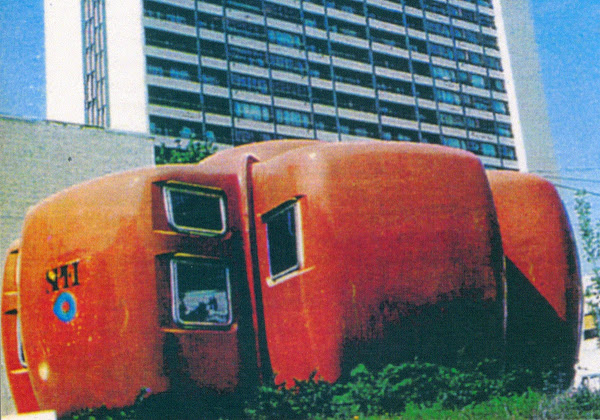

Bureau SPFI – photo: Brochure Dubigeon Normandy.

September 1964 to December 1965: Preparatory Study

December 1965 at 1968: Phase study

December 1965: Creation of technical and financial framework: Bati-Plastic

1966: Pre-market study

1966: Prototype Defense (Paris)

1967: experimental set (Holiday Village Gripp, Hautes-Pyrénées)

1967: Filing a Patent (Know-How)

1968: Sale of patent

1968: operational phase

1969: Placing manufacturing

1968-1969: Establishment of marketing and advertising network

1969-1970: Manufacturing of “Bubble 6 shells“

Paris – Tuilerie Bulle 6 shells (provenance, flu) –

Presented by the Jousse Entreprise gallery (2012)

Ionel Schein

House while plastic – Household Arts Fair Paris, (1956-1997)

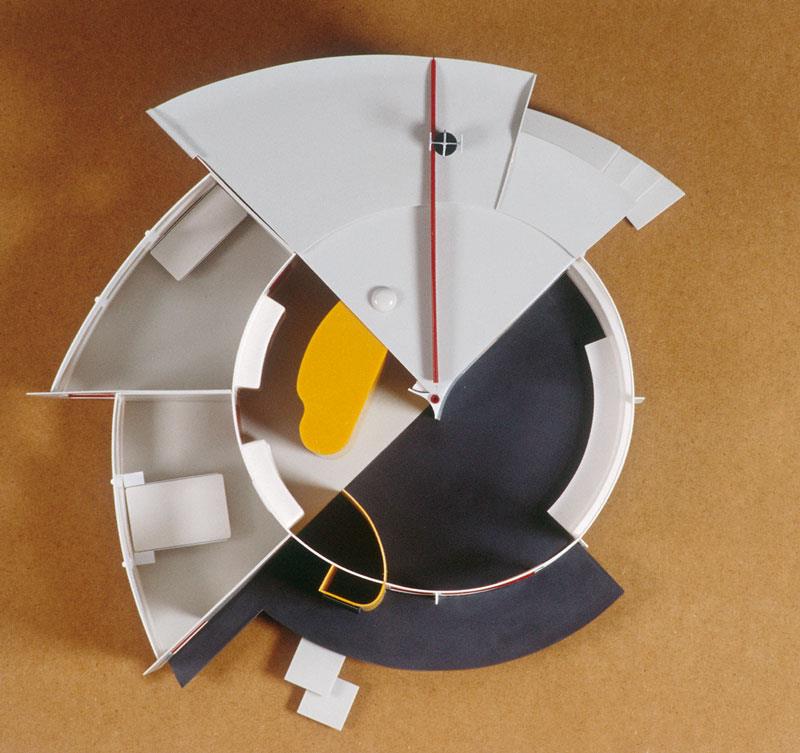

Plastic scale model, wood 27,5 x 72 x 72 cm 997 01 401(FRAC Center)

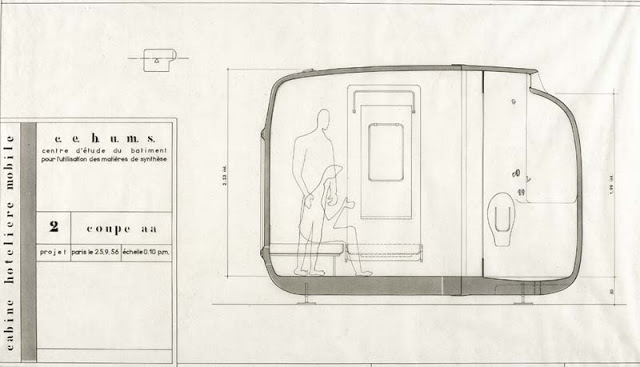

Mobile hotel cabins invented by Ionel Schein in 1956.

in parallel with the house while plastic. These cabins are considered the first experiment with a removable architectural element : the idea was that Schein hostels undergo radical changes in occupancy, and must therefore always be able to adapt to demand fluctuations. So, the ability to add or remove rooms at leisure was needed, Schein and responds with "booths" autonomous, prefabricated , fully equipped and easy to interconnect and / or a main structure. Although this project was never materialized, the precise study Schein, the arguments he had advanced so - flexibility, autonomy, assemblage –

(Pierre et Martine Jovine Tighten).

Pierre and Martine Colleu Jovine Drôme (1990). It consists of a double-glass resin shell and a polyester foam insulation Crozes Hermitage Drôme. – Hulls molded fiberglass reinforced resin.

Pierre and Martine Colleu Jovine Drôme (1990). It consists of a double-glass resin shell and a polyester foam insulation Crozes Hermitage Drôme. – Hulls molded fiberglass reinforced resin.

One of the first homes shells entirely of plastic, the "Snail House", is the work of Ionel Schein, Yves Magnant et Coulon. It is presented in the exhibition of household Arts 1956 in Paris. Autonomous cells in resin and glass fibers are tested by Pascal Haüsermann, Claude Costy, Antti Knight et chanéac. Each designs its modules which can be combined with those of other, to create diversity (scalable habitat). The production is abandoned for lack of requests. More than 70 Plastic houses are listed for prototypes 1956 at 1971 (Technology and Architecture, 1971).

One of the first homes shells entirely of plastic was introduced in 1956. More 70 plastic houses prototypes will be identified in 1956 at 1971. Autonomous cells in resin and glass fibers are tested by Pascal Haüsermann, Claude Costy, Antti Knight et chanéac. One of the plastic housing, fully completed, is that designers

THE FUTURE

FLEA MARKET SAINT OUEN

The art dealer Benoit Ramognino installed a Futuro House in the heart of the Dauphine Market in Saint-Ouen. It now serves as event space.

Futuro Futuro House or :

is a prefabricated home designed by the Finnish Matti Suuronen. Matti Suuronen (1933 Lammi in Finland - 16 avril 2013 in Espoo, Finland) is a Finnish architect and designer born in 1933. One hundred copies of this house were built between the late 1960 and the early 1970. Their distinctive shape in the style of flying saucers and their entry into airline airlock make these very popular among collectors constructions. Futuro consisted of polyester plastic and fiberglass, measures about 3 meters high 8 (then 51) meters in diameter.

Matti Suuronen plans for the design of the home-UFO Future.

After the initial success of these two bizarrada were built for an exhibition in London the same year, where they were baptized future. Following its success, 20 others were made, dont 12 were sold to non-Finns. There were plans for mass production of future UFO houses, but the oil crisis 1973 made the plastic, so that the production was not profitable.

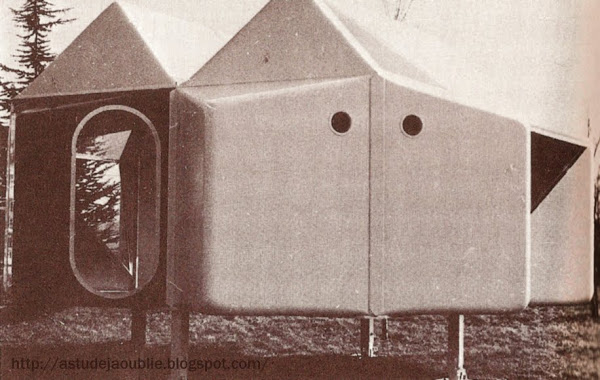

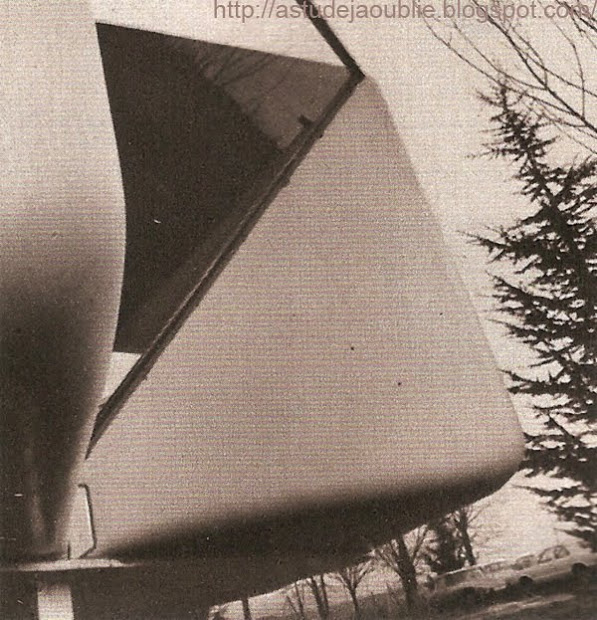

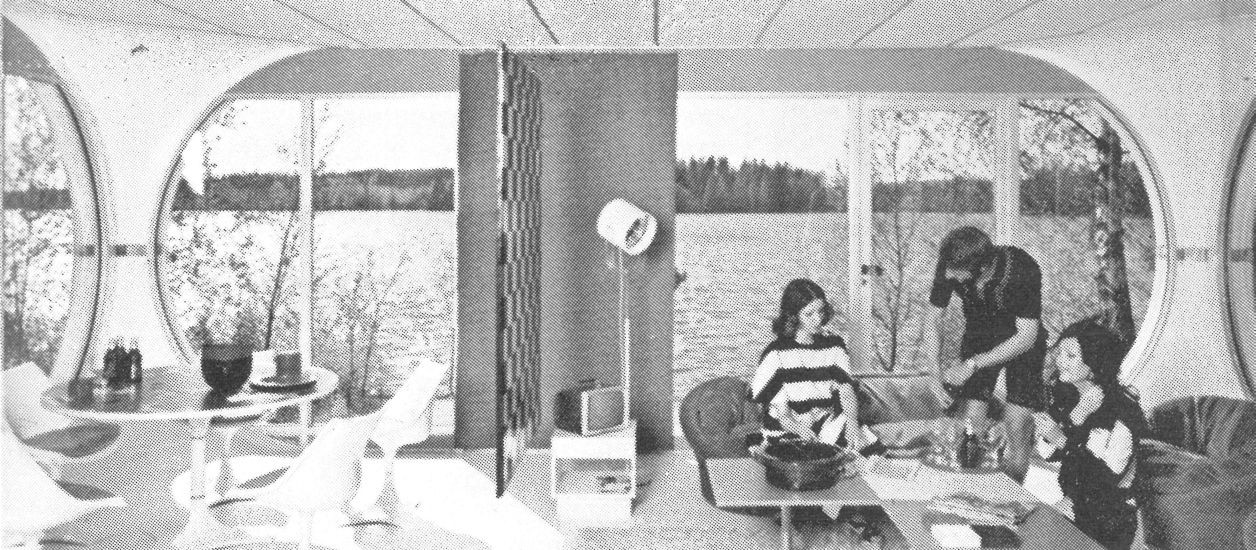

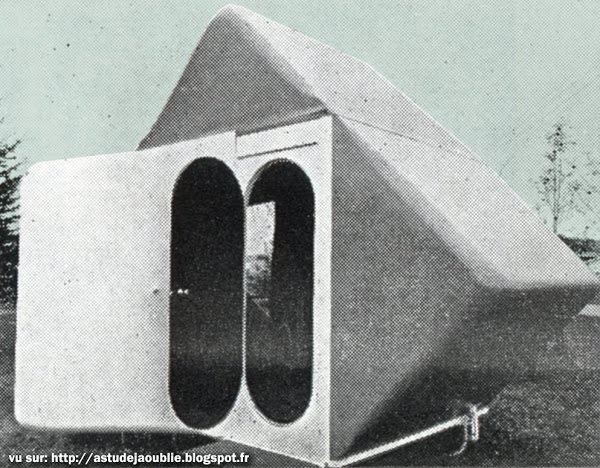

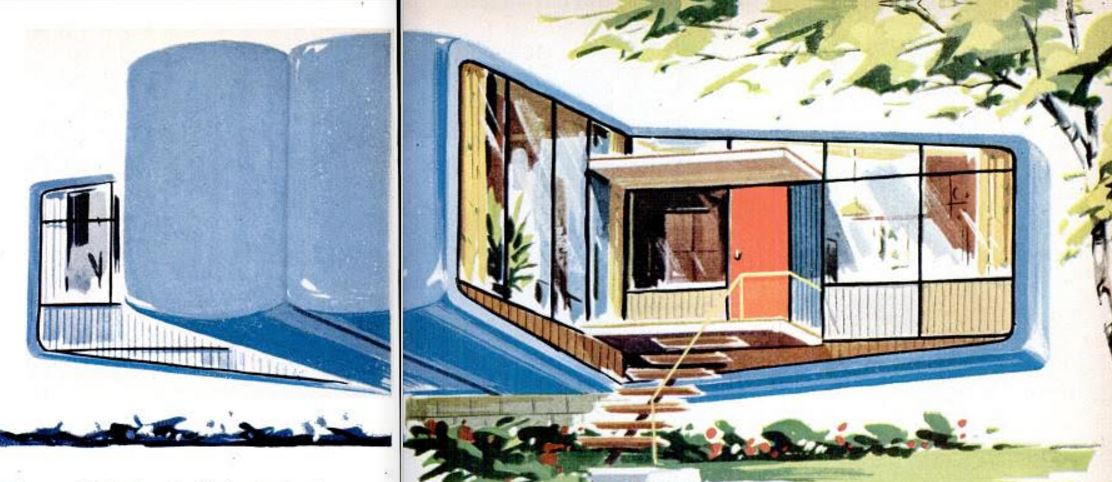

The Venturo

is a Finnish typhus fiber glass reinforced plastic,

which was designed by Matti Suuronen

Venturo ou CF-45, was the first time in 1971 in Ruotsinpyhtää by the Finnish company Oy Ab Polykem . It was part of Matti Suuronens and Polykems plasthusserie Casa Finlandia and marketed in different versions houses, kiosk and petrol station. Its area is of 45 square meters. Total production 19 Venturo houses, three of which were sold by BP for use in service stations. Today, the only known copy of Venturo remain in Sweden. It is old in bensinstationshus BP Kallinge , who 2009 was placed on the Center’ Kivik Art and after the renovation is used as the reception and cafeteria.

Venturo easy to remove, with a base in two demountable prefabricated. It has large windows, very plastic and a colored decoration in four colors to choose. residential variant came with kitchenette and built a sauna with coal plants. The basic unit, which consists of two parts totaling about four tons, can be combined with the name of the special medium.

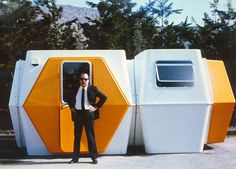

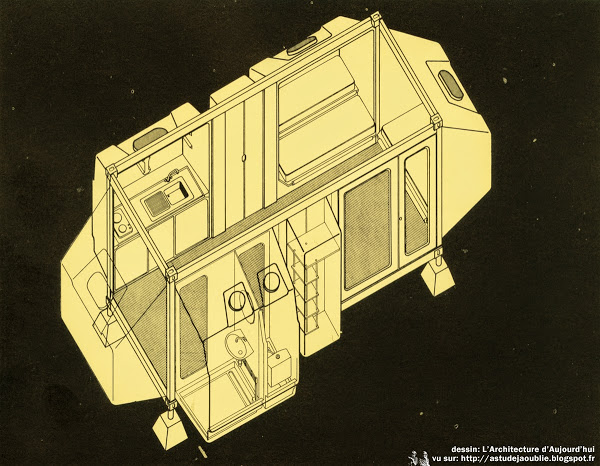

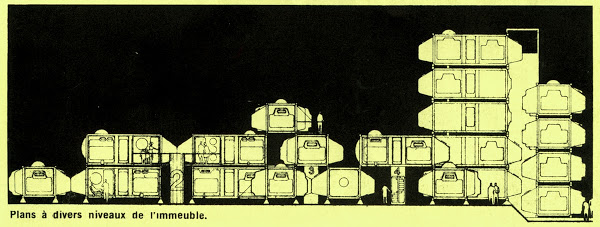

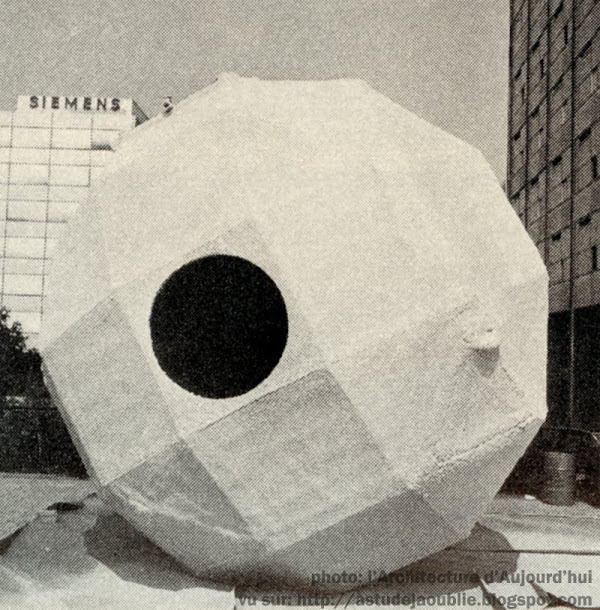

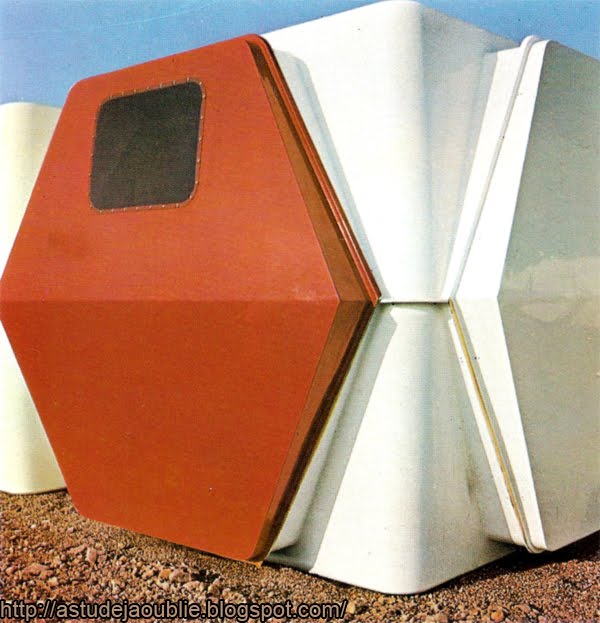

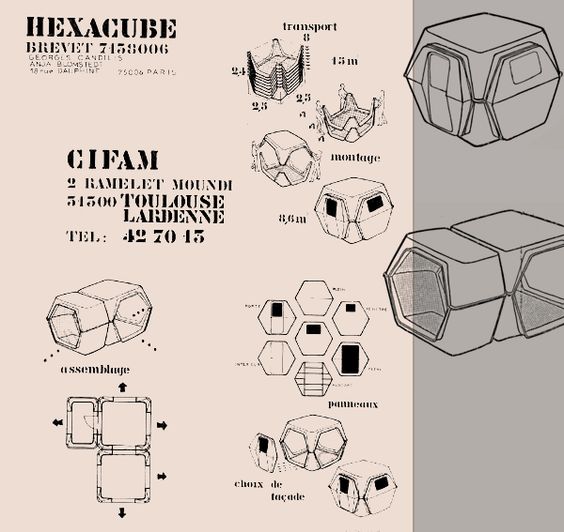

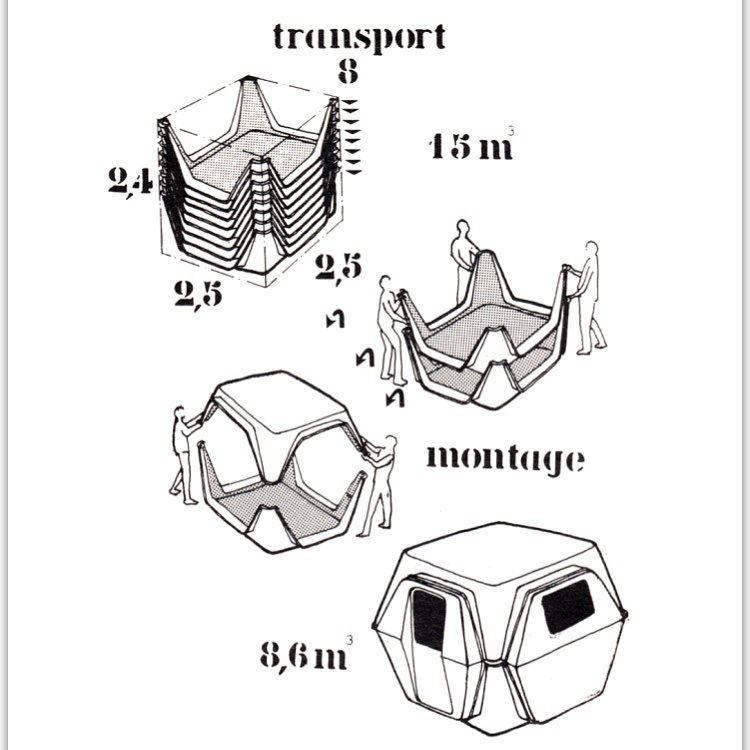

Georges Candilis (1913-1995) is an architect and urban planner Greek.

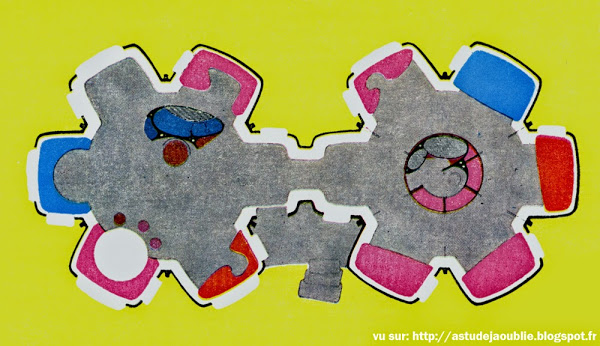

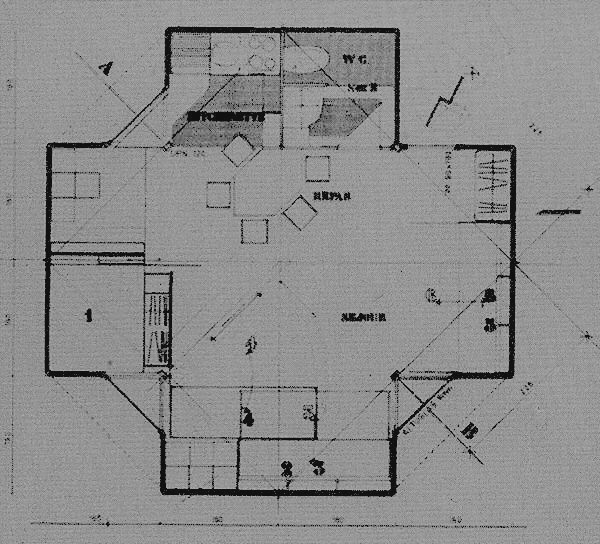

L’Hexacube – Georges Candilis , Anja Blomstedt “L’Hexacube”, prefabricated plastic cell 1968-1975. 1972 Akshibisn Georges Sandilis @ Atelier Jespers During Brfaheksakube give Georges Sandilis & Anja Blomsted 1972 Exhibition Georges Candilis @ Atelier Jespers during BRAFA

The basic unit of this construction system is dodecahedral and contains a cube inscribed 230 cm square, offering well - despite the reduced dimensions - a relatively large usable area. This cell is polyester reinforced with glass fibers. It internally accommodates a rigid PUR foam layer providing insulation. The advantage of this construction system is the multiple combinations of cell assemblies that present. A basic cell has a base surface ,7 m2. This surface can be increased by adding (at 60 or 90 °) other cells of the same size or special cells for sanitary and kitchen (3,8 m5). The cells may also be superimposed on two vertical rows. Surface maximum : 74 m3.

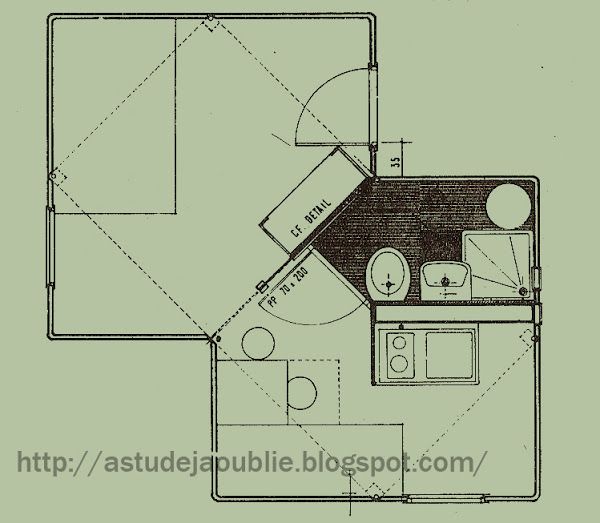

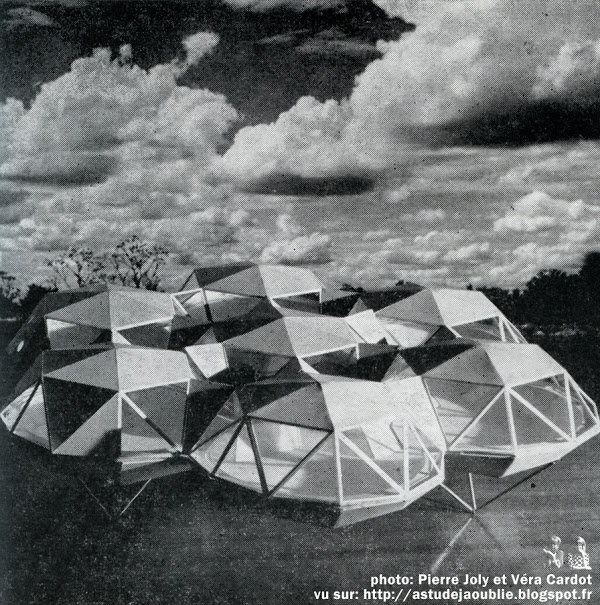

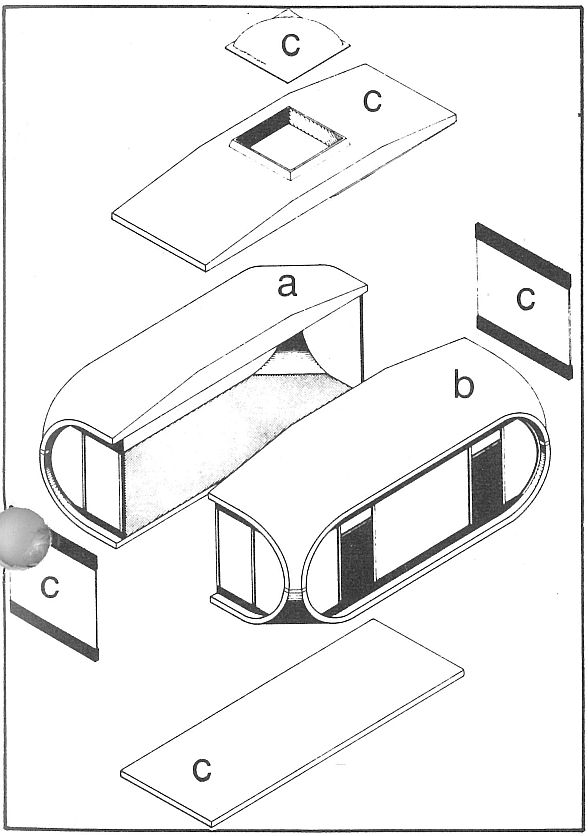

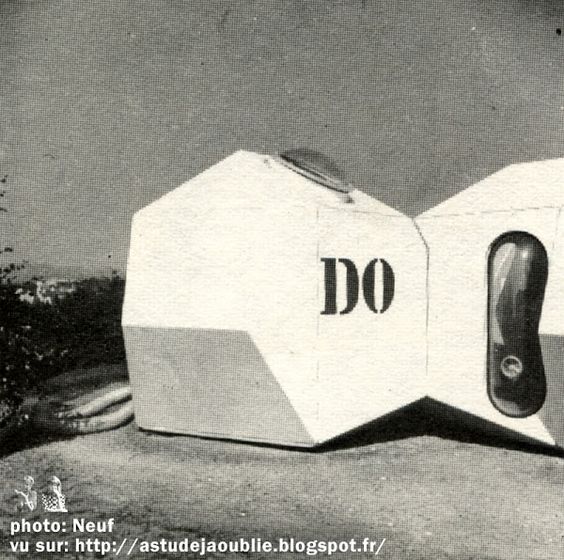

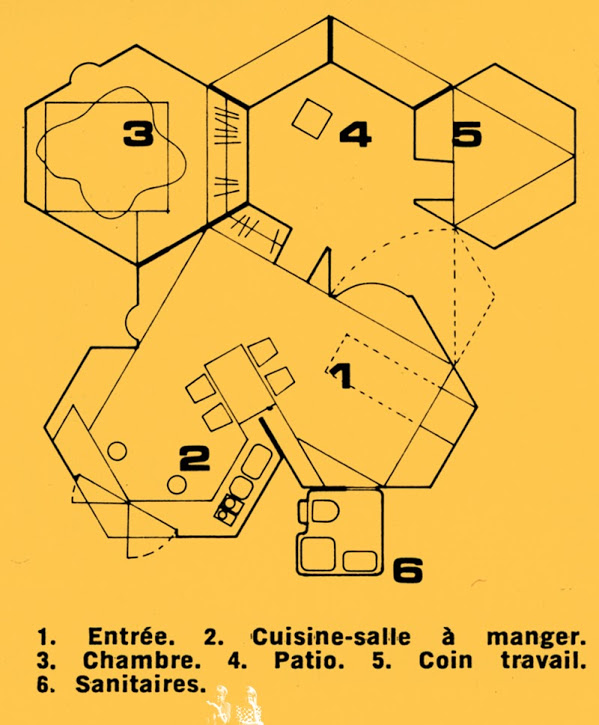

Do-Bausystem – plastic Vacation Home. Creation: 1970 – 1971

Do-Bausystem – Plastic house – J.C.. Ventalon, A.Sklenar

Do-Bausystem – Do systems – plastic Vacation Home.

Conception: Polyteam: Jean-Claude Ventalon, Ana Sklenar

University of Stuttgart.

Fabrication: fiber, Bretten, Germany.

Creation: 1970 – 1971

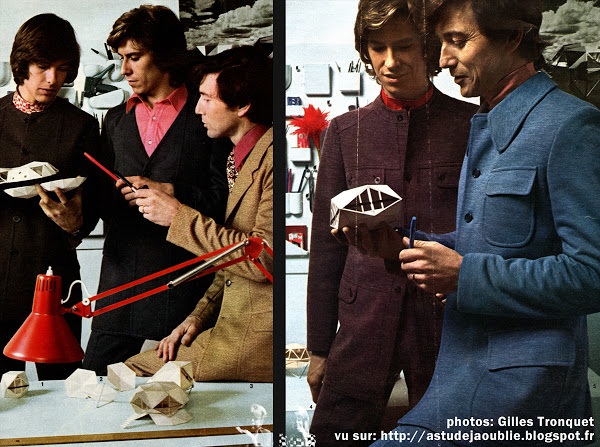

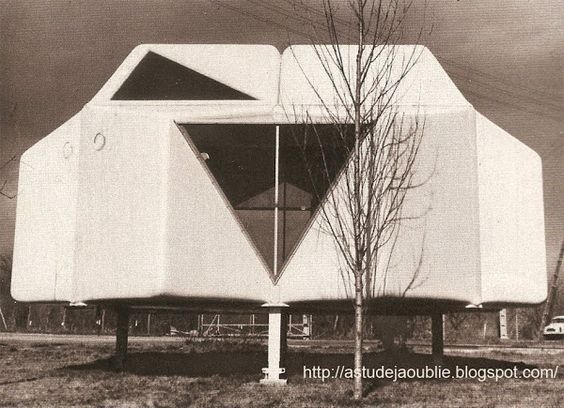

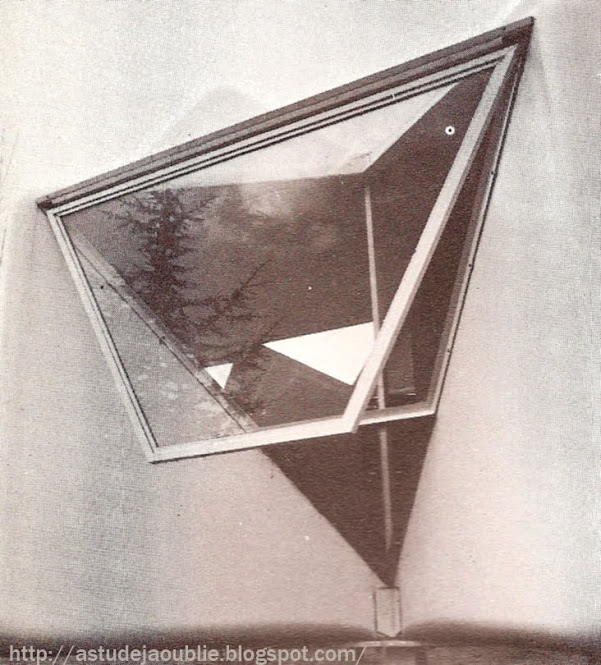

Plastic House 12E – by Atelier 4 – 1971

Plastic House 12E – 1971

The Workshop 4 – Toulouse

– House 12 E – France

Architect Workshop 4

Pierre and Robert Fort, Francis Castaigns, J. Henri Colzani et Segundo Gonzales. Toulouse

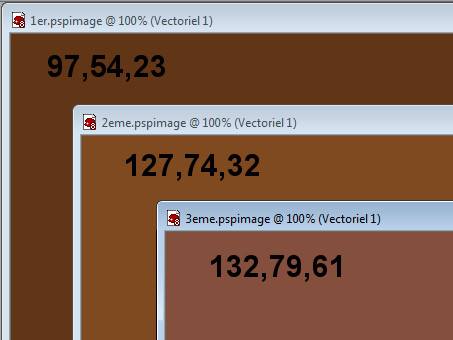

Choice of plan with 18 your m² 31 your m² 44 m²

Angular element 2.45mx 2.45mx 1.73m closed or with openings, combinable, stackable. 77 kg the element without opening, and 66 kg with opening.

Additional square element. Ledge piece with 2.45m side as GRP floor area – Rigid polyurethane foam. prototype

Documents :

– Quarmby arthur: the plastic architect. London: Pall Mall Press, 1974, page 126.

– Forum: Room cell construction system composed of self-supporting polyester moldings.

The one pictured here was made up of a dozen elements whose arrangement may vary. The weight of the element, from 70 kg, authorizes the construction on any terrain, on the water, in the dunes, in all inaccessible places and even on the terraces of buildings.

The Workshop agency 4 Fort consisted architect Pierre and his son Robert, Francis Castaing, and Jospeh Colzani and Segundo Gonzales.

“A house in twelve elements” – The home Journal – June 1971

A team of young architects Toulouse grouped in the Workshop 4, 20 Malaret street in Toulouse, has just developed, in collaboration with a large industrial company, a plastic unit allowing light constructions, transportable and removable.

The facades of which the buyer can choose the color and the roof consist of modules bolted them on a metal frame. The set is, by means of machine screws, mounted on a self-supporting floor, itself is supported by telescopic parts, or by a low wall, either by a central pillar. The plexiglass windows may be triangular or rectangular, location varies. The house finally has a dining compartment bathroom and a kitchenette.

Toulouse – Bungalow

Architects Workshop 4 Pierre and Robert Fort, Francis Castaing, Jospeh Colzani et Segundo Gonzales.

Construction: 1970-71

Presented at the exhibition “French design” at the Decorative Arts Museums of 22 October to 20 December 1971.

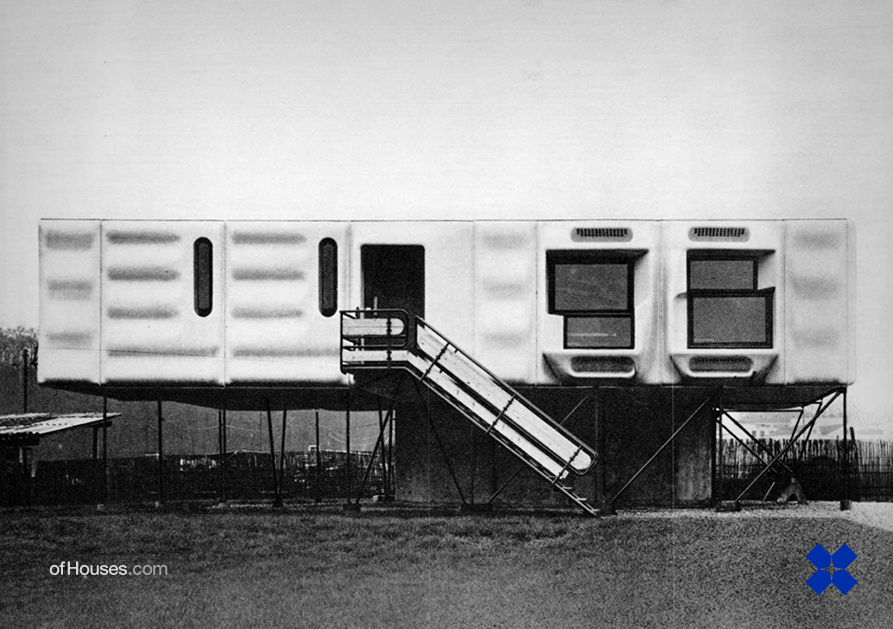

Lége-Cap-Ferret – Tetrodon – modular housing – A.U.A

Design: A.U.A (Workshop Planner and Architecture)

Jacques Berce, Enrique Ciriani, Michel Corajoud, Borja Huidobro, Georges Loiseau, Annie Tribel, Jean Tribel.

builder: Barbot group Creation: 1972

Its rectangular structure is based on 4 plots (or floats) allowing implantation “All Terrain “This steel frame was designed to container dimensions and may be juxtaposed and / or superposed to other, thus allowing a combinatorial units in three dimensions. The facade elements(sandwich laminate, polyester and glass foam

poluréthane) are, or shells integrating the various functions necessary : cuisine, health, beds, etc ... or flat panels. This Tetrodon project developed with the Société Barbot Charpente Métallique was named Tetrodon in reference to a tropical fish that swells and increases its size to make its predators.. The analysis of the project reveals a metal framework which is that of a classic container for transport by heavy goods vehicles and cargo, on which are fixed polyester growths which dilate maximally restricted space of the container. Extract of ” The year ZUP Architecture growth 1960-1973 “

The shape of the Puffer is unique and is designed in a very original way

and bold for its time.

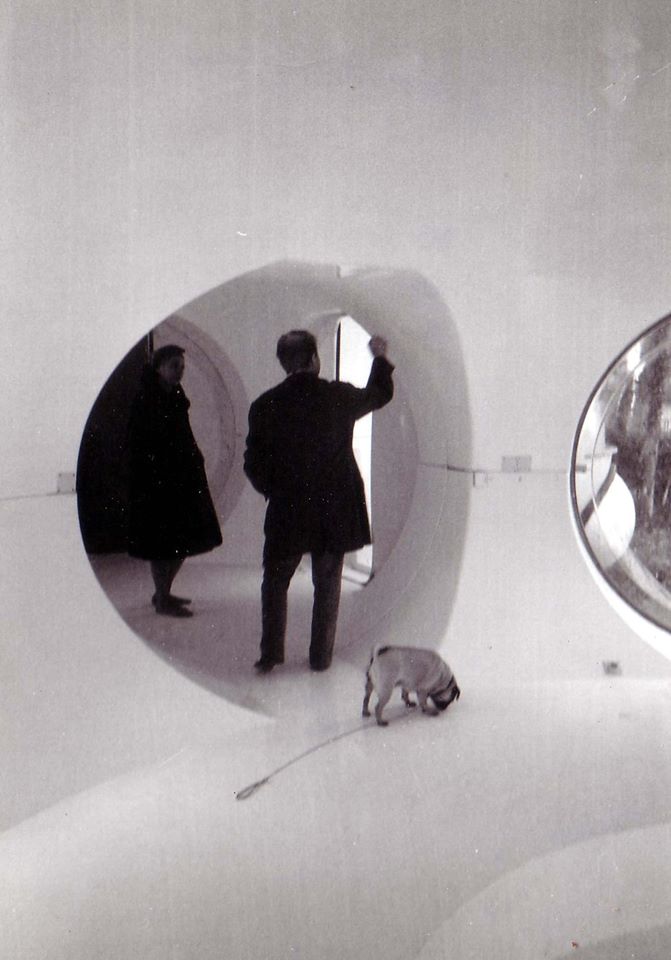

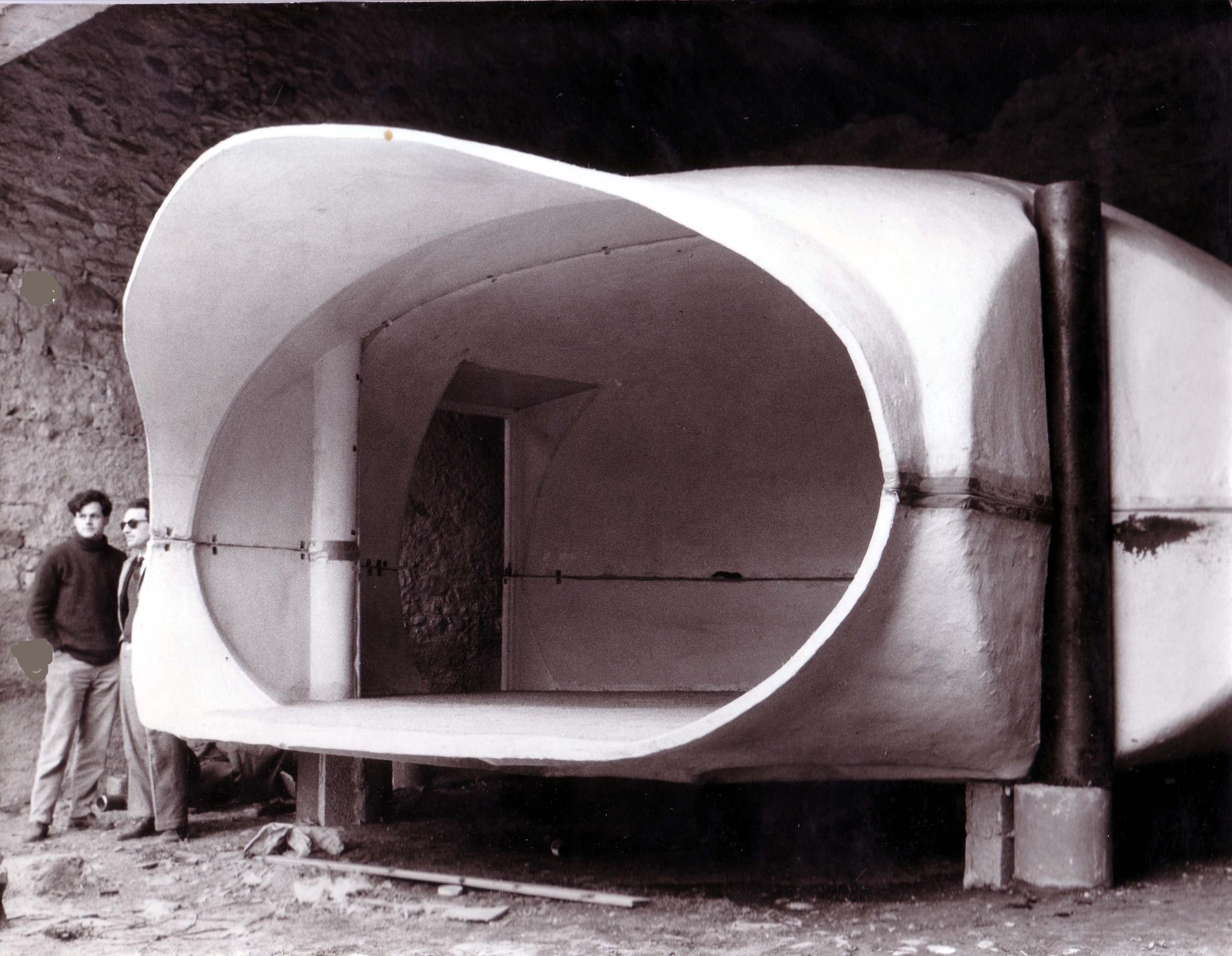

Prototype polyester house / Plastic – Pascal Häusermann

Pascal Häusermann (1936 – 2011)

Is a utopian Swiss architect specializing in homes bubbles and & rsquo; organic architecture.

Most of his designs were built in the Rhone-Alpes region, in France.

Precursor architecture Blob.

Residential oysters – Pascal Häusermann 1962

” Oysters residential lake Genster “

Pascal Hausermann his Prototype of his first plastic house in polyester

A prototype of this module in his castle in the city of Geneva.. in 1966.

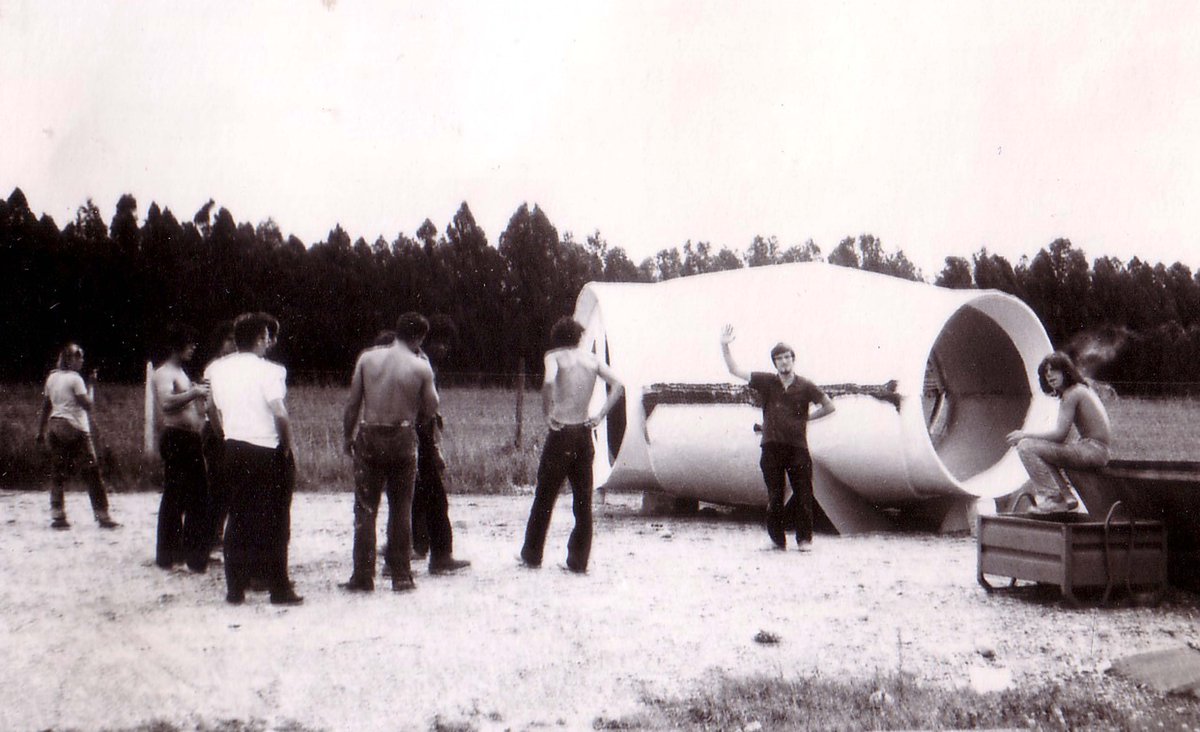

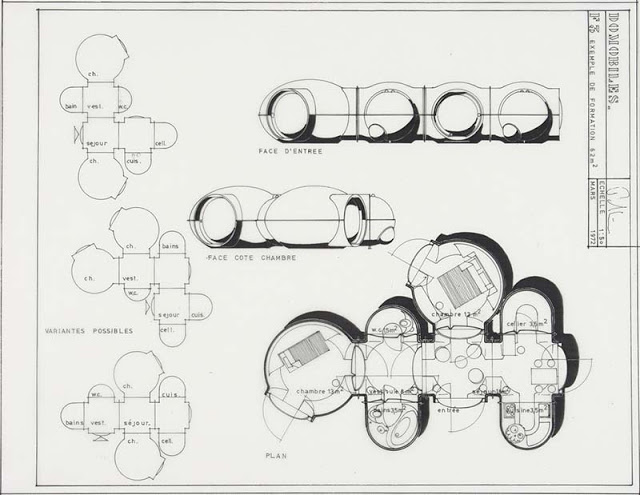

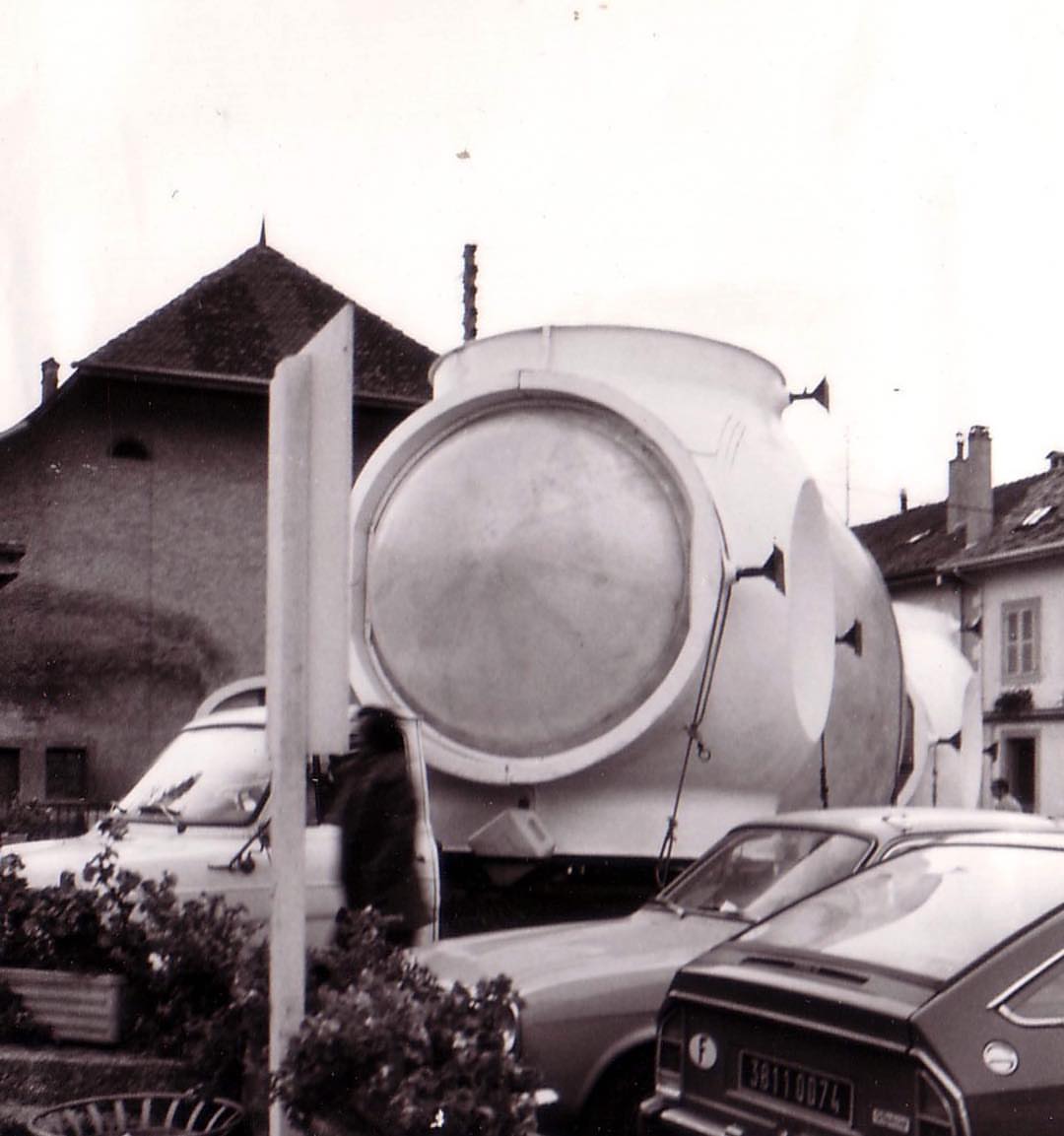

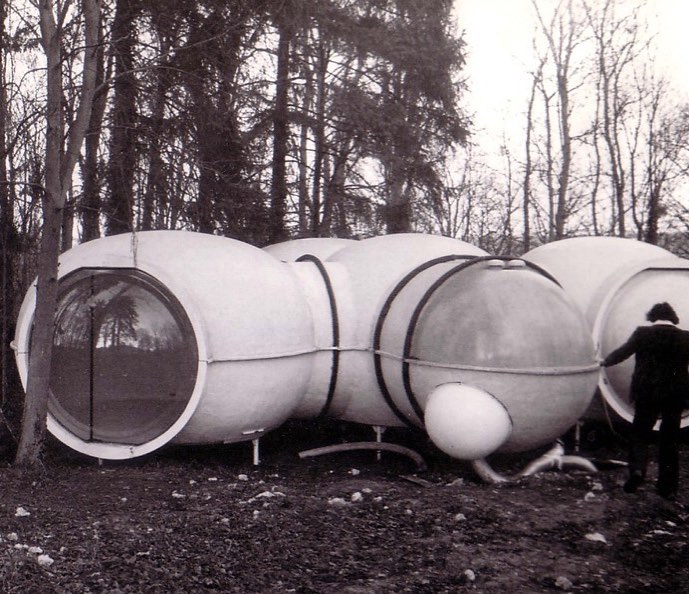

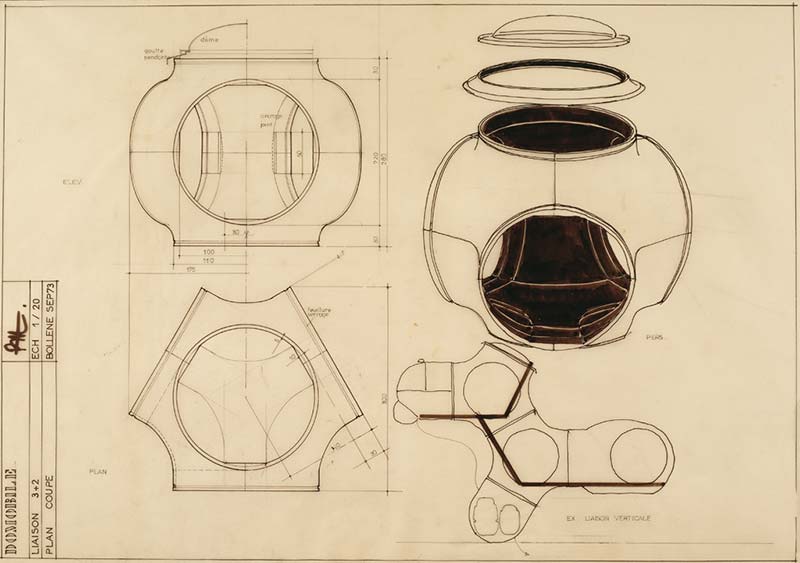

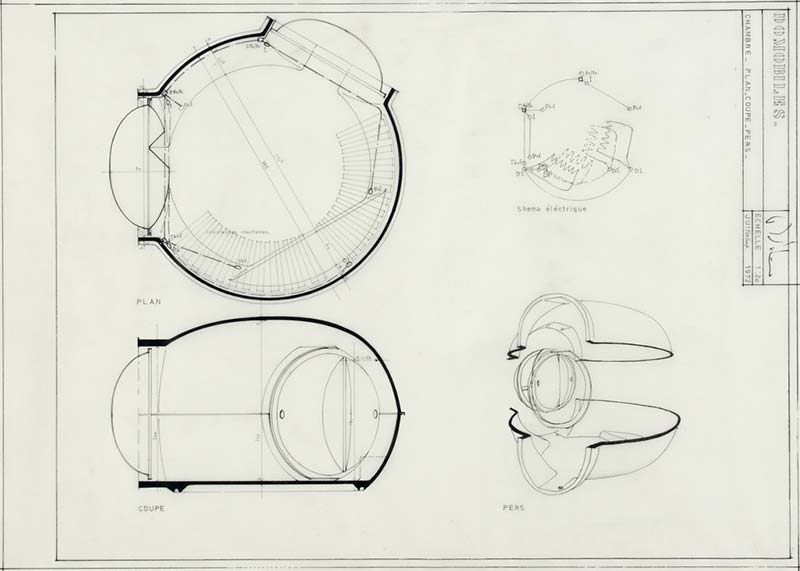

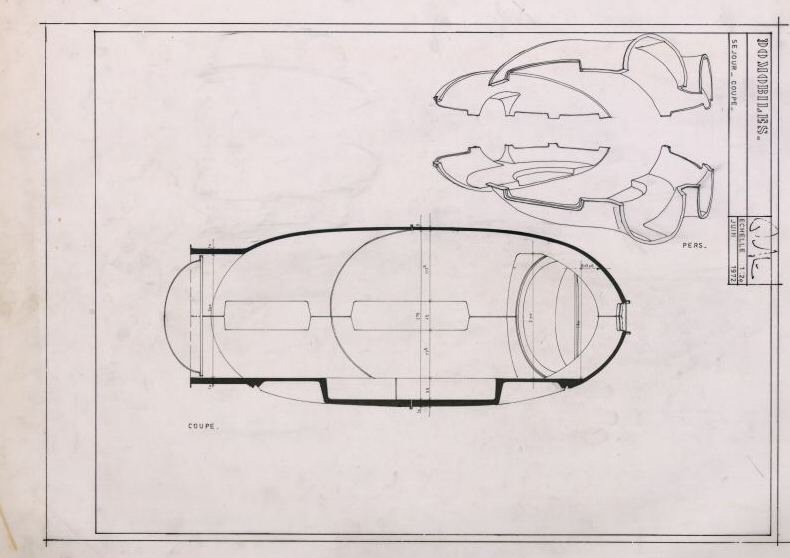

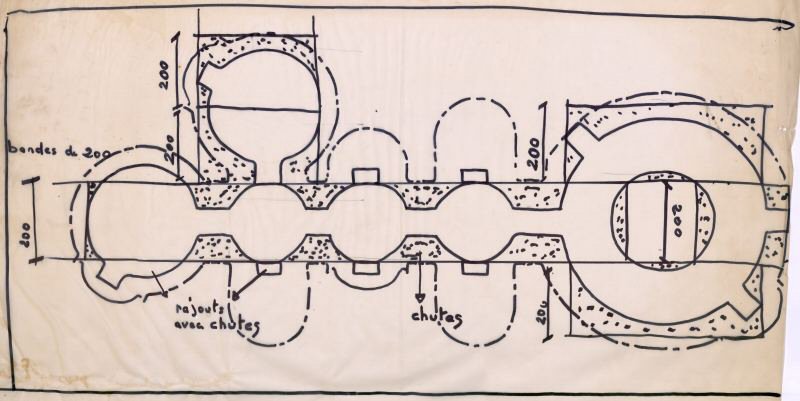

Pascal Hausermann – Domobiles

FRAC CENTER – PASCAL HAUSERMANN – COLLECTION

Arrival of cars in Douvaine

Pascal Häusermann, prototype of Domobiles in the Val d'Yerres.

Frac-Center (Loire valley) MUSEUM – WEEK 2019

These archive photographs document a student internship in Saint-Peray in 1970, led by Pascal Haüsermann. Pascal Haüsermann, on the other hand, develops the project Domobiles, nestable and mobile residential units, that can be installed quickly report then displaced, « interchangées », allowing housing to evolve with the family in residence. In 1965, after creating prototypes Domobiles, Haüsermann moreover received commands cells it plans to achieve plastic (polyurethane foam covered with reinforced polyester) and timber, but he never obtained the necessary permits to install, this did not prevent the architect to continue to draw and imagine the city of the future as an aggregate of Domobiles, developing into "plies" and gradually implanting around the ancient cities before replacing them completely.

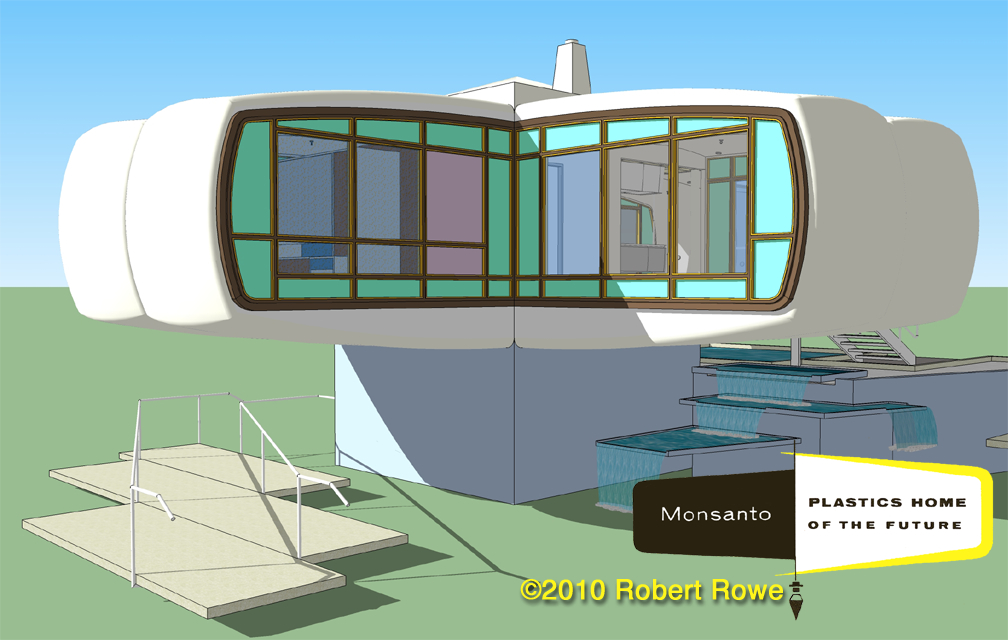

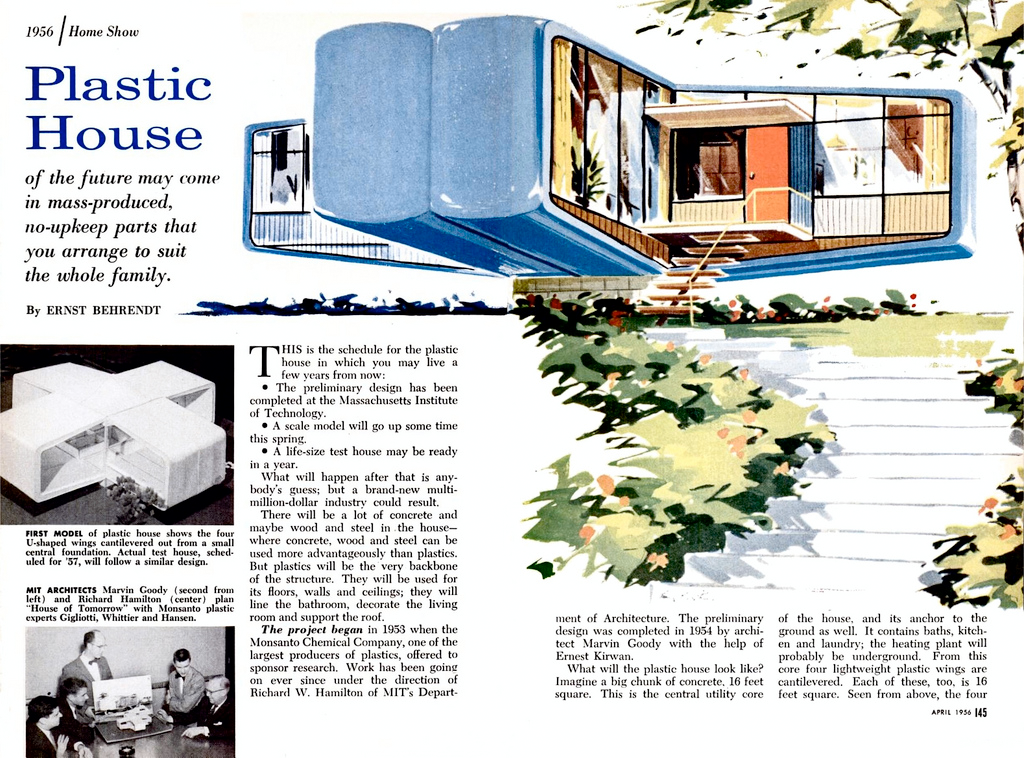

The Marshmallow buildings may have been designed by Monsanto, who created the “House of the future” from disneyland. Some people seem to remember this structure, or something very similar, used as a visitor center at the Gateway Center in downtown Pittsburgh. He disappeared in the years 1980 and may have been moved here. In 2007, this building was vacant and for sale. In 2009, it was demolished. I was told it could last a long time was also used as an ophthalmologist's office.

Monsanto House of the Future – Disneyland, 1957 – 1967

The Monsanto House was developed for the first time at MIT under the sponsorship of the plastics division of the Monsanto Chemical Company of 1953 at 1956. Marvin Goody et Richard Hamilton, two faculty members in architecture from MIT (WITH), designed the Monsanto house. The main goal of the team was to build a house made entirely of plastic. In addition, the house would also tackle the post-war housing crisis by providing affordable, modern housing to replace the poorly designed runway houses that were being built. By learning their project, Walt Disney was seduced by the concept of a synthetic model house and allowed the team to place the house in Tomorrowland, the Disneyland sector devoted to technological innovations and visions of the future and has taken control of the marketing of the new attraction.

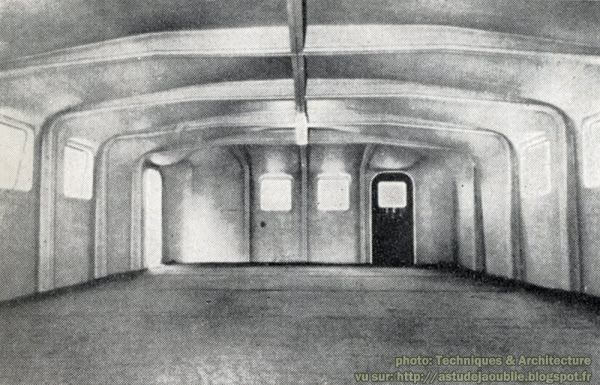

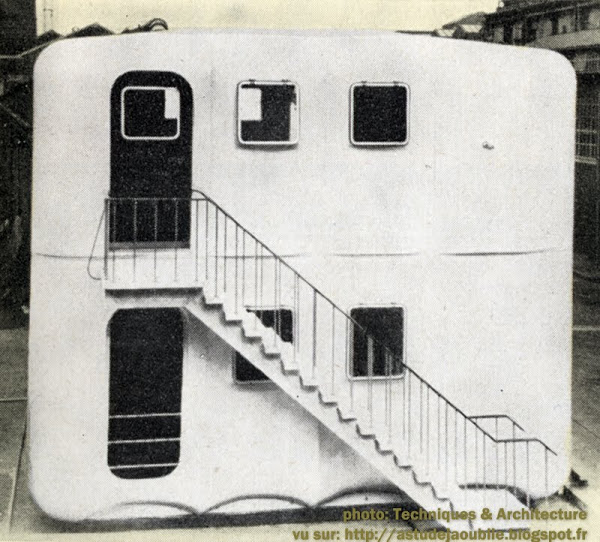

England – Plastic building – 1963 Architect: H. Stanley Smith. Construction: Mickleover of London.

Office Building for Bakelite Itd. Birmingham.

This building houses a telephone exchange and additional offices Bakelite Company. This society, Manufacturer plastics itself, wanted to show that the plastics can already be used for the construction. A similar brick building, with wooden floors and roof, would have weighed 84 tonnes. The plastic construction weighs 15 tonnes : 7 and a half tons of plastic and 7 and a half tons of steel frame. The elements are double curvature, with outer and inner layer of polyester fiberglass, and an insulating core of phenolic foam. On the ground floor, these elements are suspended from the floor of the floor and fixed to the slab of concrete foundation, upstairs, they are self-supporting and simply attached to a metallic bracket of the floor. The elements are bolted together and lined with a double flexible seal. The dimensions of this building, completed in 1963, are : length 11,30 m; width 7,05 m; height 5,70 m.

Building for British Antarctic Expeditions.

It is white to mount a floor building, to serve as a biological laboratory in Antarctica. This type of construction is derived from that of Birmingham, published above with, however, an insulating core of 38 mm, double glazed windows and doors Special resistant snowstorms. The fact that plastic items floating in the water greatly simplified the problem landing on site of this building, because the island Signey to which it is intended does not have fitted dock. The molds had to be changed and 72 complete elements were manufactured in less than five months.

Texts and photos: Techniques & Architecture – 1964.

Texts and photos: Techniques & Architecture – 1964

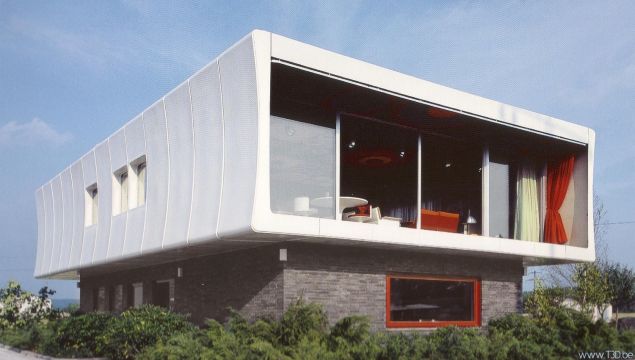

HOUSE FIBER GLASS 1970, DEVELOPMENT DESIGN & THE PROTOTYPE :

The construction of the prototype in May 1968 for the shell 13 roof panels and wall GRP 26

(Photo: W. Feierbach)

Axonometry prototype, original device (Image: house plastic fg sample folder 2000)

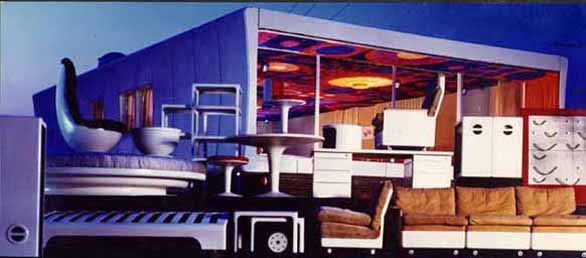

All Fiberglass Interior Design and Architecture. Wolfgang Feierbach "plastic house FG 2000″ was built in Altenstadt Germany in 1968-1970

The modular prefabricated house Kunststoffhaus FG-2000 in 2010.

The prefabricated modular Kunststoffhaus FG-2000 at night around 1970.

by Dieter Rams.

This is an amazing prefab modular fiberglass home most of the furniture was custom made by architect designer Wolfgang Feierbach with a few exceptions: the sofa and chairs in the living room were designed by Dieter Rams (620 series produced by Vitsoe), the bathroom furniture in red fiberglass was created by Rohm and Haas (it was in commercial production for two years and has even been sold in the US). We believe that the ceiling carpets were inspired by Verner Panton and produced by Mira-X.

Isle of Wight – Modular Plastic House – Wight Plastics

Isle of Wight – Modular plastic housing

Architect: Wight Plastics Limited

Project / Construction: 1968 – 1971 Isle of Wight – Modular Plastic House – Wight Plastics

Isle of Wight – Modular plastic housing

Architect: Wight Plastics Limited

Project / Construction: 1968 – 1971

Modular plastic housing

text and photos -1971.

Image Credits: Wolfgang Feirbach, Marketing Design fiberglass +, Teddy T3RD in Belgium, NOVA68.com.

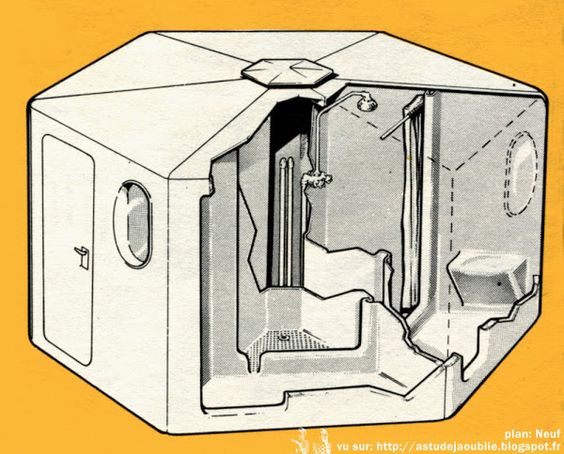

This module is specifically designed to accommodate six shower compartments. Each compartment comprises an outer door and an acrylic resin window. The shower room is isolated from a changing room by a curtain. The pipe and the fitting are accessed through a door on the back of each compartment.

Description: The basic module consists of 6 wall panels and 6 roof elements. The area covered is 14 m2. The internal height in the center of 2,60 m. All reached a weight of 295 kg. To allow easy transportation, the module is available in the form of 2 parcel 2 m X 3 m X 0,45 m.

Installation is quick : 2 men, inexperienced, can assemble a module 2 hours. It can be installed on any flat surface with no special foundations. In case of permanent use, it is necessary to provide for bolting the module on a concrete surface. The walls and roof panels are sandwich elements : 2 polyester faces reinforced with glass fibers and core of expanded PVC 25 at 127 mm in thickness according to the intended use.

The assembly of the various elements is by means of galvanized steel bolts : sealing is provided by profiles of synthetic material which are compressed when tightening. The price of a basic module (ex works) would be about 46.000 FB without interior equipment.

Studies undertaken in late 1968 for the manufacture of semi-permanent portable led home a British firm to develop a versatile module with a set of essential features for the uses to which it could finally meet : emergency housing in the regions devastated by a natural disaster, emergency operating theater, cottage exhibition, holiday home, etc.

This module had to be light (to allow the potential drop), it had to be easy to assemble in the most difficult conditions, he was able to combine with other modules, finally, be cheap. A prototype was built on the basis of data collected. From this basic module, the firm is now able to manufacture different models tailored to specific needs : cottages for summer camps, operating theaters, cold rooms, Campaign workshop, etc.

prefabricated plastic cell

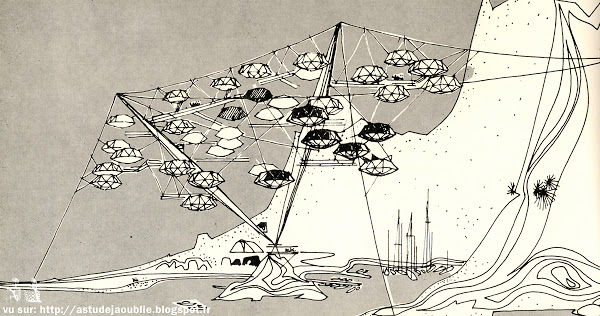

Architect: Paul Maymont

Project: 1963 – 1964

individual housing:

the facades of this construction can be changed at will by replacing industrialized elements.

A utopian holiday village located on an inaccessible rocky coast against a steep cliff. A spider web of cables called clinging to two masts including elevators and emergency staircases, supports suspended individual houses. The connections are made through gateways. Constructive Elements of a School Grouping Six Classes. The production by industrialized panels facilitates transport and assembly. Organic growth was free; orientation and sunshine pose more problems. The use of plastics gives absolute freedom to architect. A look at some achievements in this area, it may seem that the boundaries of science fiction have been taken. But these boundaries are precisely those of the future century who created the limits of the old urbanized worlds. Such constructions are far from the deserts of ice and sand that men will live tomorrow.

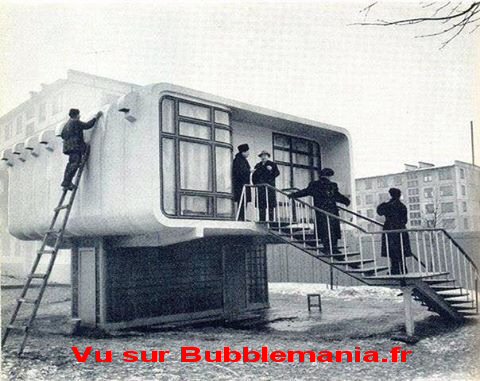

A Soviet prototype of a plastic house built in the early 60.

This house completely unique experimental plastic was built in 1961 Leningrad (Saint PETERSBOURG). It was actually a two-stage, but the lower level was a technicality and was used for heating and ventilation equipment. The walls of the first floor were made from reinforced filled framing glass blocks, while the second stage is entirely made of plastic material, its height above the ground is 2, 20 meters.

Plastic House Dieter Schmid was designed 1963.

Schmid was fascinated by the possibilities offered by the construction with standard components. Plastic House – Biberach, Germany 1963.Plastic House was completely prefabricated and portable. It was the first home of its kind in Europe. Schmid and his family lived in the house, at the periphery of Biberach, in Germany, pendant 11 years, before it was sold and demolished in 1975.

Plastic House – Biberach, Germany 1963.

EXPOSITION & INFLATABLE STRUCTURES years 60’s

International event on art, technology and the imagination of the air in all areas : land vehicles and equipment, sailors, air and space / devices, appliances and tools / Art work / constructions, architecture / furniture / toys and beach accessories / works of artists / advertising items / arrangements for games and celebrations. Exhibition organized with the UTOPIA group at the Museum of Modern Art of the City of Paris / ARC of 1 the 30 mars 1968.